Getting it right ensures efficiency, compliance, long-term reliability, and better patient outcomes. There are numerous variables to consider.

Engineers have a critical role to play in ensuring medical vacuum systems meet the demands of health facilities. It’s important to choose the right size of system from the outset — the system needs to meet today’s requirements and be capable of meeting future needs.

Revamping or expanding a system due to increased sizing needs could be very expensive and difficult after installation. It could also be disruptive to the medical facility. Engineers should consider a range of parameters and be sure to utilize available tools when selecting a medical vacuum system to ensure peak performance.

New medical devices

As hospitals adopt new and more advanced medical devices, their need for more capacity in their vacuum systems can continually expand. Engineers should anticipate increased usage and design systems that can handle new equipment without compromising performance.

The top priority for medical vacuum systems is NFPA 99 compliance. Regulations are constantly updated, leaving many healthcare facilities with outdated medical vacuum systems that don’t meet the latest regulatory changes, which could lead to inefficiency and potential violations. Additionally, their systems might not keep pace with new medical devices that require expanded capacity.

“There is often a lag between state compliance requirements and facility upgrades. Engineers should proactively check whether their system design aligns with the most recent NFPA 99 changes,” said Pat Coyle, Medical and Laboratory Gas Consultant, Pattons Medical. “This includes such factors as pressure loss limitations, proper equipment placement and system expansion requirements.”

External catheters

External catheters are driving a significant change in vacuum system sizing requirements. The PureWick System, for example, is typically used for patient incontinence or to help wean patients off indwelling/Foley catheters. They can be used to assist limited night-shift nursing staff.

From a vacuum system perspective, each catheter adds anywhere from .88 – 1 SCFM to the total calculated demand. If a facility is using 40 catheters, that’s an additional 40 SCFM. If the original system was sized for 50 SCFM, now it needs to handle 90 SCFM — almost doubling their initial peak calculated demand.

“If engineers don’t factor in the use of external catheters, they risk under-sizing the vacuum system, which can lead to serious performance issues after installation,” Coyle said. “A vacuum system that’s too small is difficult and expensive to retrofit once it’s in place.”

Engineers should be aware of NFPA 99 code changes to design systems in accordance with the latest standards. For example, a recent update reduced the allowable pressure drop (vacuum loss) in piping due to the increased use of external catheters. Engineers should make sure the pipes are properly sized to handle the required SCFM capacity. If they fail to

account for pressure loss, the system may not function properly.

“The key takeaway for engineers is that vacuum system sizing is changing due to the increased use of external catheters. They need to stay ahead of these changes when designing new systems,” Coyle said.

Questions engineers should ask before installation:

Elevation considerations

Engineers should factor in their geographical location when sizing a system. Changes in elevation and altitude can significantly impact vacuum system performance. At higher elevations, thinner air causes systems to run hotter and lose vacuum efficiency.

Specifically, systems lose approximately 1” Hg for every 1,000 feet of elevation. Certain technologies struggle to operate efficiently above a certain altitude — unless they are specifically sized for high-altitude use.

Dry graphite vane pumps, for example, struggle above 4,100 feet due to running excessively hot. This wears down the graphite prematurely and can damage the internal chamber of the pump. Claw vacuum pumps sized 10 horsepower and above experience reduced efficiency at high altitudes, dropping from a maximum vacuum of 24” Hg at sea level to 19” Hg at 5,000 feet. Smaller horsepower systems can pull a deeper maximum vacuum, so it may be appropriate to multiplex smaller systems around the 5,000-foot elevation mark.

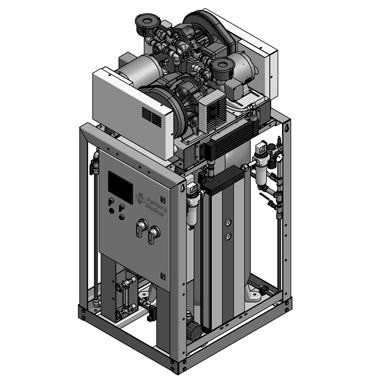

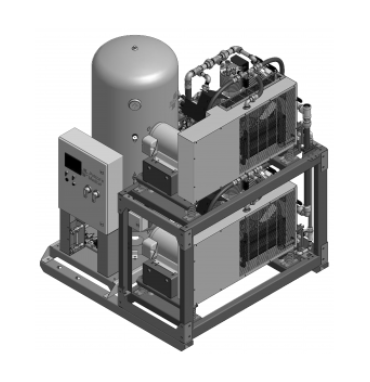

Equipment choices can mitigate these challenges. For elevations much above 5,300 feet, oil-lubricated vacuum pumps may be the best option. Pumps with variable frequency drives (VFD) optimize vacuum performance based on current needs. Pattons Medical advises installing a VFD on any claw pump above 4,000 feet and using an oil-lubricated vacuum for elevations above approximately 5,200 feet.

Engineers toolkit

Specifying engineers have many tools at their disposal to calculate the proper sizing for medical vacuum systems.

A Medical Vacuum Sizing Calculator , for example, helps determine peak demand and proper sizing for a facility, taking into account a wide array of variables. It enables you to enter external catheter counts or elevation measurements, for example, to help engineers size appropriately.

A Medical Vacuum Systems in High Altitudes chart offers engineers an easy way to upsize their peak calculated demand based on a facility’s elevation.

The most important asset an engineer can have, though, is a relationship with an expert. Consultations with the experts at a medical vacuum system provider can provide insights into the latest NFPA 99 updates, design recommendations, value-engineering solutions and more.

“It’s important to ask the right questions early,” Coyle explained. “Proper planning that accounts for all the variables that can affect medical vacuum systems can prevent a lot of costly headaches down the road. By working with an expert, engineers can ensure they design a system that is compliant, efficient and reliable for decades to come.”