Hospitals and healthcare facilities are evolving at a rapid rate. Engineers should anticipate that future needs will be greater than today’s.

Expansions. Emergencies. Technological advances. These are all good reasons to expect

that a facility’s medical requirements can rapidly grow overnight. For some hospitals, the

need for ventilators during COVID-19 was a wake-up call. For other institutions, such as

those in growing population areas where patient populations surged, the lesson was that

expanding a medical air and vacuum system is not simple, nor inexpensive.

"Expandable systems protect hospitals from the unknown — whether it’s a pandemic, a

new technology, or a surge in patient load,” said Greg Hood, Vice President – Pattons

Medical. “Designing to minimum demand isn’t enough anymore. Facilities need flexibility

built in from day one."

Designing expandability into a medical air system is prudent, and it can save a facility from

future disruption. Hospitals frequently add new ICUs, patient wings and surgical suites.

When these sites need more capacity, expansions need to be simple and timely.

Similarly, healthcare facilities need to expand to accommodate the growth in new medical

devices, such as external catheters and ventilators. These devices require great SCFM

capacity and can push older systems to their limits.

Medical gas consultants work with engineers to ensure expandability is designed into a

system from the start. This means that a medical air or vacuum system can be scaled up in

the future by adding pumps, compressors, capacity, alarms and control systems — without

a full system redesign or overhaul.

“When we’re brought in early, one of the first things we ask is what’s on the drawing board,

such as future wings, towers or ICUs. Even if it’s three years out, we help engineers design a

system that can grow with the facility, not one that must be torn out and replaced,” Hood

said.

The cost of inadequacy

The cost of designing a medical gas and vacuum system without expandability in mind is

high. It could lead to expensive retrofits. Completely removing and reinstalling a new

system costs more than designing it to be expandable in the first place. It’s extremely

disruptive in medical environments. Retrofits could require temporary shutdowns in

facilities or compromise patient care.

There is also the opportunity cost. Healthcare facilities generally put a premium on ESG

(Environmental, Social, Governance) programs. They might include equipment that is not

as efficient or sustainable as other options, increasing energy consumption, and in turn,

emissions. They could miss out on valuable grants or rebates that incentivize energy

efficiency as part of sustainability initiatives or reward forward-thinking designs.

“We’ve walked into hospitals that were locked into undersized systems because nobody

planned for expansion. By the time they’re ready to grow, it’s too late — they’re tearing out

walls and missing out on efficiency incentives they could’ve had with just a little foresight,”

Hood said.

Preparing for the future

Consultants work methodically to ensure a system is expandable for future needs. They

integrate modern control panels that can be pre-designed to control additional pumps or

compressors that can be later added without major overhauls to infrastructure.

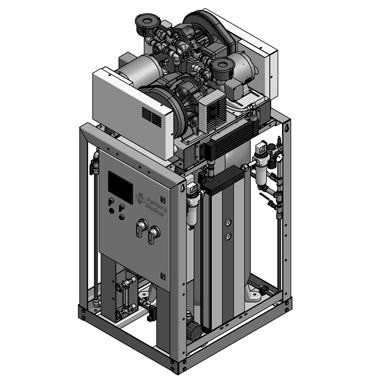

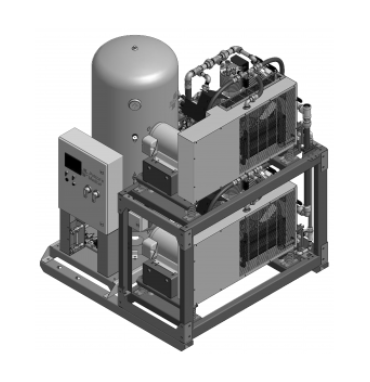

They institute modular system architectures, such as duplex systems expandable to

triplex, to add capacity by simply installing a new module. They over-design systems to

include larger distribution piping for increased flow rates and extra space in mechanical

rooms to accommodate additional units. They ensure that electrical infrastructures can

handle more electrical load and more power.

When consultants work with engineers, they ask questions like:

Is there a tower expansion planned in the next five years?

How many ventilators or catheters could the facility need in an emergency?

Is there adequate space to add more control panels, pumps or compressors?

What percentage of the facility’s demand is currently being used?

Are there any regulatory changes that could influence equipment decisions?

Has the hospital searched for grants, incentives or rebates?

“Expandable design isn’t just about hardware — it’s about strategy,” Hood explained. “We

help facilities think ahead. We don’t just ask questions; we help engineers answer them.”

Expandability as a principle

Designing medical gas and vacuum systems to a minimum design is no longer acceptable.

Whether it’s the looming possibility of emergency surge situations, game-changing medical

devices or facility expansions, expandable systems are the new standard.

The effects are wide-ranging: economic, practical, sustainable and patient-driven. When

expandability is a principle of design engineers, hospitals and healthcare facilities are

ready for whatever the future may hold.

“If you’re not thinking about expansion today, you’re planning for disruption tomorrow,”

Hood said. “Working with a good medical gas consultant ensures the best possible

outcomes for engineers, facilities and patients alike.”