MEDICAL SCROLL AIR COMPRESSOR

Pattons Medical is committed to providing the best in medical and laboratory gas solutions in the market. Pattons Medical designs and manufactures high-quality and customizable medical air compressor packages for health care facilities across the USA. Pattons Medical products meet or exceed NFPA 99 and CSA standards and are UL approved. One of Pattons Medical’s many strengths is our capability to work with our engineers to develop special medical air packages to help meet the particular application or specifications of hospital needs.

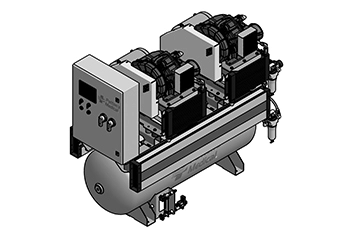

Pattons Medical scroll compressors are built to offer reliable, oil-free, clean, and dry air for your medical or laboratory application. Pattons Medical scroll air compressor are designed for ease of maintenance, small footprint, and quiet operations. Pattons Medical’s scroll configurations have the smallest foot print in the market complete with desiccant compressed air dryers, filters, dewpoint monitors, and CO monitors.

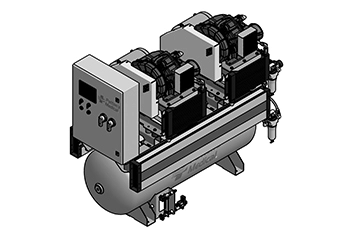

- Duplex

Horizontal Tankmount

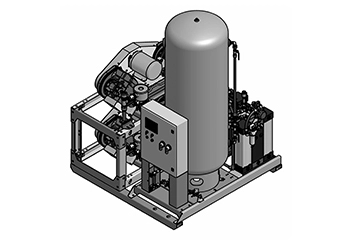

- Duplex

Vertical Tankmount

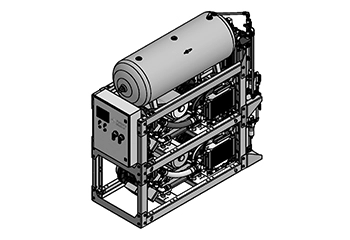

- Duplex

- Triplex

- Quad

- Pentaplex

- Hexaplex

Single Point Connection

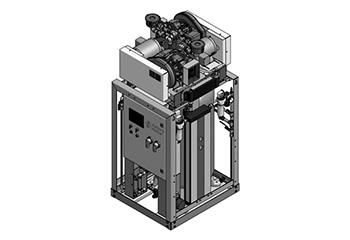

- Duplex

Space Saver

- Duplex

- Triplex

- Quad

- Pentaplex

- Hexaplex

Single Point Connection

Introducing System Health, a standard feature on all Pattons

Medical scroll compressor packages

Pattons Medical offers the System Health feature for all of our medical and laboratory air compressors.

Functionality of your medical air compressor is critical to patients safety. Pattons Medical recognizes this crucial aspect and presents the cutting-edge System Health standard feature, exclusively designed for medical and laboratory air compressor systems. With the integration of Human-Machine Interface (HMI) on control panels, medical professionals gain real-time access to vital information concerning the performance and ambient conditions of these systems. In effect, this vigilant monitoring empowers users to receive timely alerts and preemptively address any issues, safeguarding against potential system failures.

The Key Parameters Monitored by Pattons Medical System Health Encompass:

- Ambient Temperature

- Current Consumption

- Dew Point Analysis

- Carbon Monoxide Levels

- Active Pump Status

- Precise Pressure/Vacuum Levels

Don't compromise on the reliability of your medical gas equipment. Rely on Pattons Medical System Health for peace of mind and the highest standard of patient care.

Request Technical DataWebinar On Compressed Air Technology

Webinar on Medical Air Compressors

WHY CHOOSE PATTONS

MEDICAL ?

CERTIFIED & TRUSTED MEDICAL AIR SYSTEMS

Pattons Medical air compressor products meet or exceed NFPA 99 and CSA standards and are UL Approved.

CUSTOM MEDICAL AIR PACKAGES

Pattons Medical works with you to create medical air compressor packages that meet your health care facility’s needs. If our standard products do not exactly fit your requirements, we will work with you to develop special medical air compressor packages to comply with your particular specifications or applications.

DECADES OF EXPERTISE

Pattons Medical was established in 2008 and has manufactured medical gas equipment in Charlotte, North Carolina for over 15 years. Pattons Medical team brings to the table a combined expertise of 400+ years in medical gas solutions. We are committed to quality and innovation; we look forward to working with you and your needs to be your preferred partner for Medical Gas Equipment.

REQUEST INFORMATION

ABOUT PATTONS MEDICAL

Pattons Medical was established in 2008 and has manufactured medical gas equipment in Charlotte, North Carolina for over 15 years. Pattons Medical team brings to the table a combined expertise of 400+ years in medical gas solutions. We are committed to quality and innovation; we look forward to working with you and your needs to be your preferred partner for Medical Gas Equipment.

Pattons Medical works with you to create medical air compressor packages that meet your health care facility’s needs. If our standard products do not exactly fit your requirements, we will work with you to develop special medical air compressor packages to comply with your particular specifications or applications.

FAQ

Where are your products manufactured?

Pattons Medical manufactures all medical and laboratory air and vacuum packages in Charlotte, NC. Our product team takes pride in the work they do. Each unit is tested before departure to ensure hospital and health care facilities across the US have reliable and quality medical gas equipment

Can you help with design of medical gas system?

Our Medical and Laboratory gas consultants have years of experience designing, sizing, and specifying medical gas equipment and always available to help! Be sure to reach out to them early in your design process to ensure you have the latest medical gas technology and meet NFPA 99 code.

What is the design process from site surveys to drawings to final handovers?

A brief overview is that the first thing a facility does when they decide to build, expand, or remodel, is hire an architect. The architect will put together some drawings of the building, shelf space, and other details. Then, they will hire the mechanical, electrical, and plumbing engineer. The medical gas design takes place most of the time by the plumbing designer. From there, you would have to start looking at outlet counts, where they are needed and begin sizing. It’s important to try to have a list of questions that can almost apply to any project to give to an owner when you have the opportunity. Then, you can start the design process of laying and sizing the pipe, sizing the source equipment, and going through revisions before you get to construction. After this, you’ll go through getting submittals from the contractor, and making sure your specifications have come in.